FOR IMMEDIATE RELEASE

Friggi America is pleased to announce the appointment of

Steven Blay as Executive Vice-President, effective February 2026.

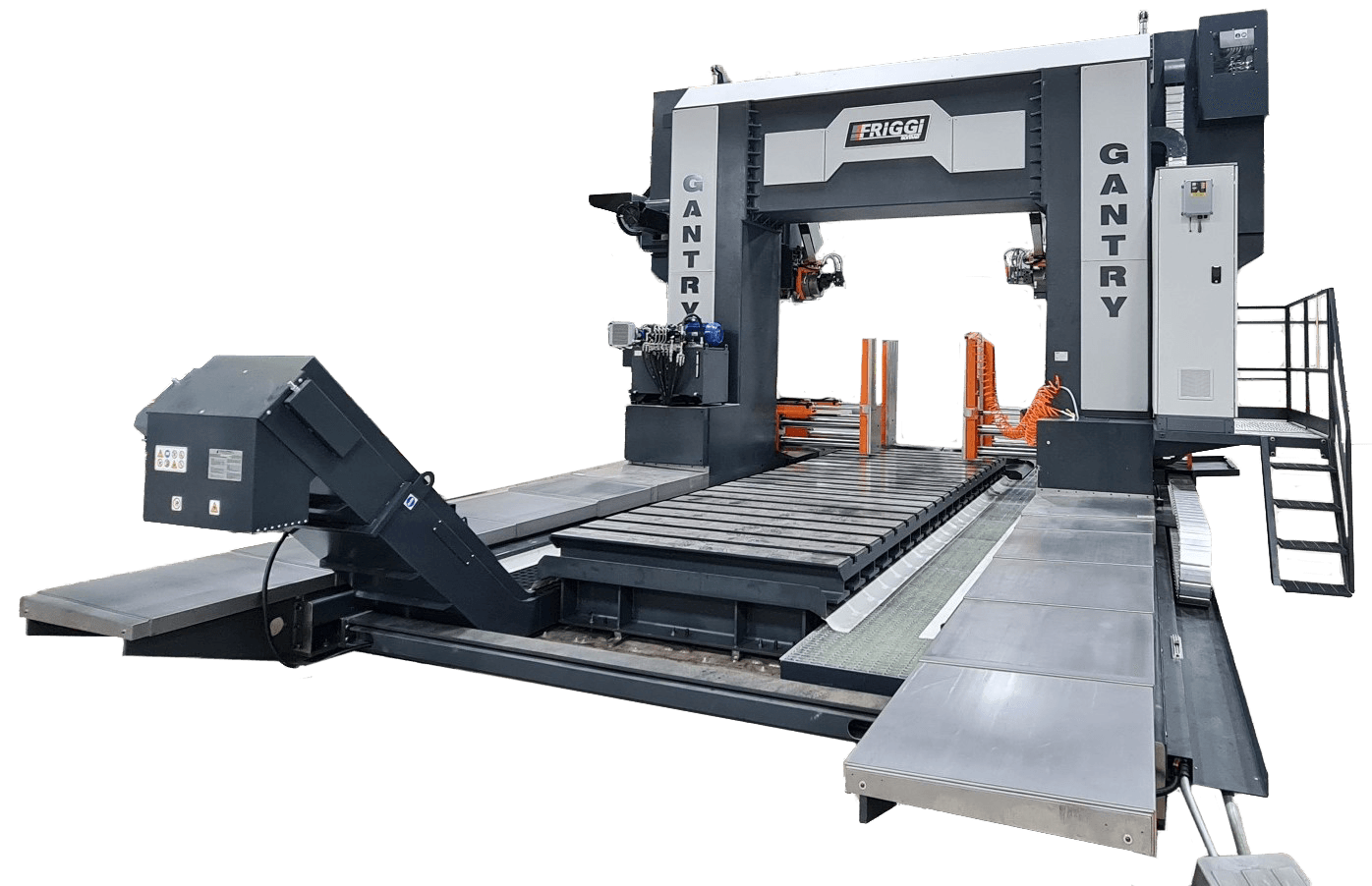

Introducing a full range of Saws to cut bars, plate, slabs, blocks, structural, and coils with capacities and options to meet your production requirements

- A solution for all your cutting needs

Precision, productivity, reliability

FRIGGI AMERICA., provides premium metal and aluminum cutting solutions. With over 80 years experience in the design and manufacturing of machinery, we offer a complete line of horizontal and vertical band saws, and industry-leading high-speed carbide saws.

FRIGGI was the first to offer many time-saving features, one of which is the rotating guides. This feature enables vertical, horizontal, angle, and even radius cutting – all done without having to reposition the material – a HUGE time-saver, and cost saver.

Our newest line of high-speed carbide saws will cut aluminum, steel & exotic alloys with industry best cutting rates. Whether the application is to cut ferrous or non-ferrous metals for ingot, bar, block, plate, or coils, we offer the best solution for our clients’ production needs.

LATEST TECHNOLOGY

Client feedback and our in-house experts allow us to constantly look for and update our steel and aluminum cutting machinery with the best available cutting technologies so that performance is never a compromise.

PERFORMANCE

FRIGGI's product innovation & knowledge of the metal cutting industry is our key in providing application-driven solutions to our clients. All our metal cutting machinery is designed to improve your profitability by maximizing productivity and uptime while lowering operating costs.

SPARES & CONSUMABLES

At Friggi America, after-sales service is always a priority to us. We have factory-trained service personnel ready to deploy when needed.

We try our best to act quickly and efficiently for spare parts requests. Many spares are in stock ready to ship, next day service. To order parts, simply email a request and we'll get to it as soon as we can. Contact Us

SVC Vertical SAW

If you are looking for versatility in cutting, this is the saw for you.

Available for cutting speeds for aluminum, steel or exotic alloys.

Cutting Titanium

& exotic Metals

ONL SERIES SAW

– HIGH SPEED CUTTING ALUMINUM

This video shows the ONL660 cutting a 6” round solid bar in about 6 seconds!

Watch it to believe it.

What Our Clients Are Saying

Kapital Steel - Indiana

“Friggi sales/support have been great to work with. Understanding of the machine and what we do makes getting answers very simple. They work with us on every issue we have ever had regardless of the reason why it happened. We are very happy with the support we receive and thus is the reason why we currently have another Friggi machine on order!”

Jerome Kusbel, President

Vista Metals Corp.

Produces aluminum billets up to 42" dia and rectangular slabs up to 42" thick.

“Between pricing, lead time and general communication, Vista Metals was satisfied with the whole package they (Friggi) really back their product.”

Charles Shepherd Plant manager

Progressive Alloy Steels

Cutting hardening grades of plate 15-5, 13-8 and 17-4 with capacity from 48" to 24' length and up to 18" thick.

“We needed a saw in a short amount of time. A company we worked with introduced us to Friggi. We were faced with 6-9 month delivery with another saw manufacturer but Friggi had the piece of equipment we wanted ready to go. The pairing has left Progressive Alloy "incredibly happy."

Bruce Olson President

Active Industrial Solutions

Makes molds, dies and components for automotive, consumer products, oil and gas, aerospace applications.

“Our Friggi saw is probably the most profitable machine tool in our company. The Friggi has helped us gain competitive edge but the key thing the machine does is significantly reduce our roughing hours.”

Gary Hottot VP Sales & Marketing

Niagara Specialty Metals

What they do: Specialty steel manufacturer

What do they cut: Stainless steel, titanium, tool steel

Why did they select Friggi: Faster cutting, better blade life, easier to use control, better tolerance and cut quality

“Pre- manufacturing questions answered fast and customizations were easy tailored to our exact needs. The service technician is the best field service tech we have ever dealt with across all our machines. Set up and modifications have been flawless. Responsiveness from your whole team is unmatched! "

Andy Sharp

ww.nsm-ny.com

Send Your Messages and Inquiries

to Friggi America

HAVE ANY QUESTIONS?

Friggi America would love to hear from you. Get in touch and see what we can do for you.